How Pallet Racking Systems Improve Safety and Efficiency in Your Warehouse

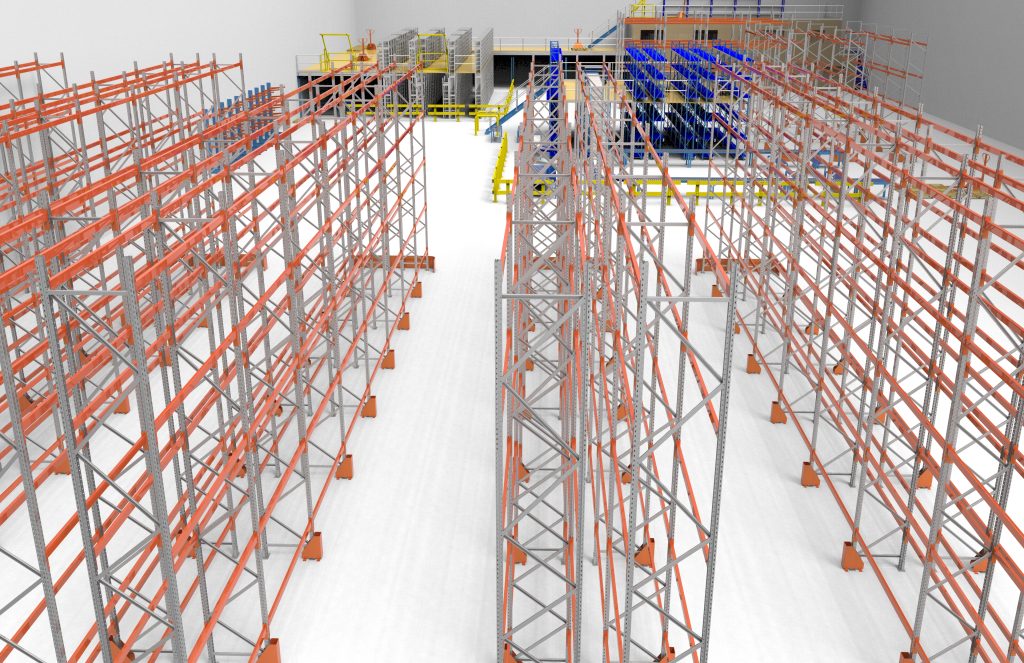

In a fast-paced warehouse environment, ensuring the safety of your staff and maintaining efficient operations are top priorities. One of the most effective ways to achieve both is by implementing a well-designed pallet racking system. Not only do pallet racking systems maximise space, but they also create a safer, more organised work environment. Let’s explore how these systems can significantly improve both safety and efficiency in your warehouse.

1. Maximising Space for Enhanced Workflow

Space is one of the most valuable assets in a warehouse, and an organised space leads to better efficiency. Pallet racking systems are designed to take advantage of vertical storage, which allows you to store more products without expanding your floor area. By optimising space, you reduce congestion in aisles, making it easier for forklifts and workers to navigate the warehouse.

With a clear and organised layout, products are easier to locate, pick, and store, speeding up processes and reducing time wasted searching for items. This streamlined workflow enhances overall productivity while reducing the likelihood of accidents caused by cluttered aisles or misplaced products.

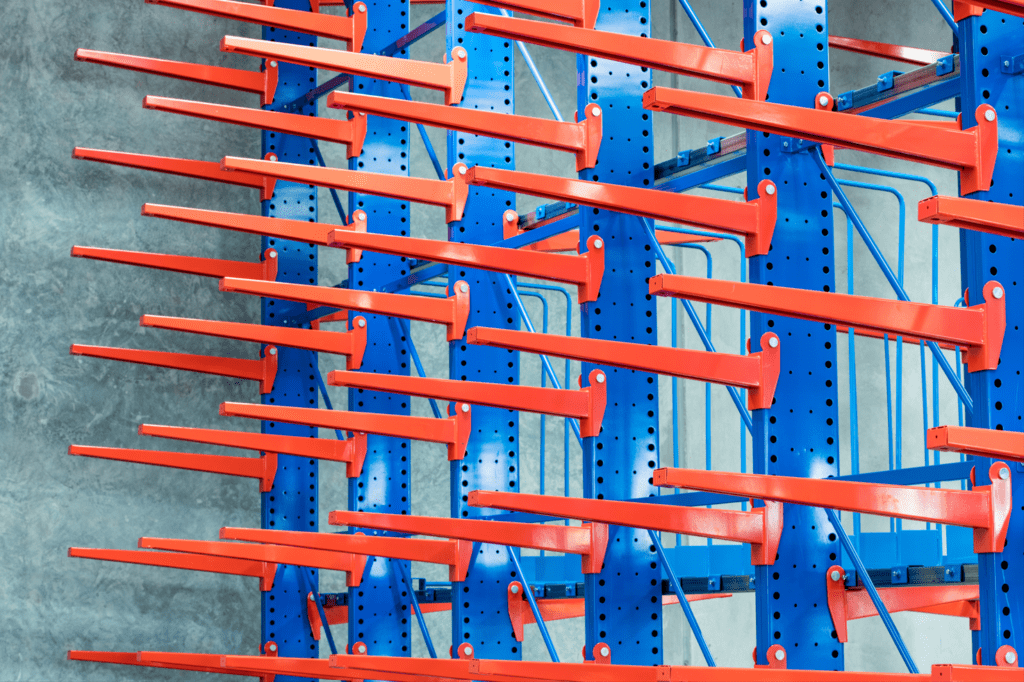

2. Improving Safety with Structured Organisation

A well-structured pallet racking system reduces the risks of accidents by providing designated storage areas and preventing products from being haphazardly stacked. Without proper storage, there’s a higher chance of items falling, which can lead to injuries or damaged goods. With racking systems, heavy or bulky items are stored securely, minimising the risk of collapse or falls.

Additionally, pallet racks can be customised to suit the type of goods you’re storing. For example, heavier items can be stored on lower levels, preventing overloading at higher levels, which could lead to instability. Racks also come with safety features like wire mesh decking or pallet stops to further ensure product security and reduce the chance of accidents.

3. Reducing Physical Strain on Workers

By keeping products organised and easy to access, pallet racking systems help reduce the physical strain on your workforce. Items stored at the right height mean fewer awkward lifts and less bending or reaching, which can reduce the risk of injury. This ergonomic advantage not only ensures the safety of workers but also increases their efficiency, as they can complete tasks faster and with less effort.

For warehouses using forklifts or other equipment to move heavy loads, pallet racks help create designated pathways, reducing the risk of collisions or accidents caused by tight spaces or sudden obstructions.

4. Enhancing Equipment Efficiency

Pallet racking systems aren’t just beneficial for workers—they also improve the efficiency of the equipment you use. With a well-structured racking layout, forklifts can move through the warehouse more easily, reducing the risk of accidents and damage to both goods and equipment. Efficient pallet racking layouts mean forklifts have clearer paths and can retrieve and store pallets quickly and safely, minimising downtime and boosting productivity.

5. Enabling Inventory Management

A key component of any efficient warehouse is accurate inventory management. Pallet racking systems allow for organised storage, which can be categorised and labeled, enabling faster access to products and easier stock rotation. This improved organisation reduces the chances of mistakes in picking orders and can also aid in maintaining accurate stock levels, preventing overstocking or stockouts. In turn, efficient inventory management translates to fewer delays and improved order fulfillment times.

6. Compliance with Safety Regulations

Warehouses are subject to strict safety standards, and pallet racking systems can help ensure compliance with these regulations. Many pallet racking systems are designed with safety in mind and are built to meet industry standards, offering peace of mind that your warehouse is up to code. Regular inspections of your racking systems also help you identify any potential issues before they become major safety risks.

Conclusion

Investing in a high-quality pallet racking system does more than just improve storage capacity—it creates a safer, more efficient warehouse environment. By reducing the risk of accidents, improving workflow, and making better use of available space, these systems are essential for any warehouse aiming to improve its operations. With Allrack’s expertise in pallet racking solutions, you can ensure your warehouse is both safe and efficient, contributing to the long-term success of your business.

Interested in learning more about how Allrack can help you optimise your warehouse storage? Contact us today to explore your options.

How Pallet Racking Systems Improve Safety and Efficiency in Your Warehouse Read More »