In today’s fast-paced supply chain environment, efficient storage solutions are more crucial than ever. Whether you’re running a warehouse, distribution center, or retail facility, the ability to store, manage, and access products quickly can significantly impact the bottom line. That’s where pallet racking comes into play—an unsung hero in the logistics world. Let’s explore why pallet racking is the backbone of modern logistics and how it can drive your business forward.

Maximising Space Efficiency

One of the biggest challenges in any warehouse is the effective use of space. Pallet racking systems, including selective pallet racking and drive-in racking, allow businesses to optimise vertical and horizontal space. Instead of letting unused overhead areas go to waste, pallet racking transforms vertical space into a valuable asset. By maximising storage capacity, it helps businesses store more products in less space—cutting costs on real estate and improving overall efficiency.

Scalability and Flexibility

As businesses grow, so do their storage needs. Pallet racking systems offer unmatched scalability, allowing companies to easily expand their storage capabilities without a complete redesign of the warehouse. Whether you’re handling heavy machinery or light goods, there are various configurations to accommodate different weight capacities and sizes. The ability to scale up or down based on inventory needs makes pallet racking systems a long-term, flexible investment.

Improved Workflow and Productivity

A well-organised warehouse is key to improving workflow and productivity. With pallet racking systems, products can be easily sorted, stored, and retrieved. Forklifts and other handling equipment can navigate aisles efficiently, reducing the time it takes to locate and move products. This streamlined operation leads to faster picking times, fewer bottlenecks, and a smoother overall supply chain. In modern logistics, where time is money, these systems prove invaluable for ensuring fast, accurate order fulfillment.

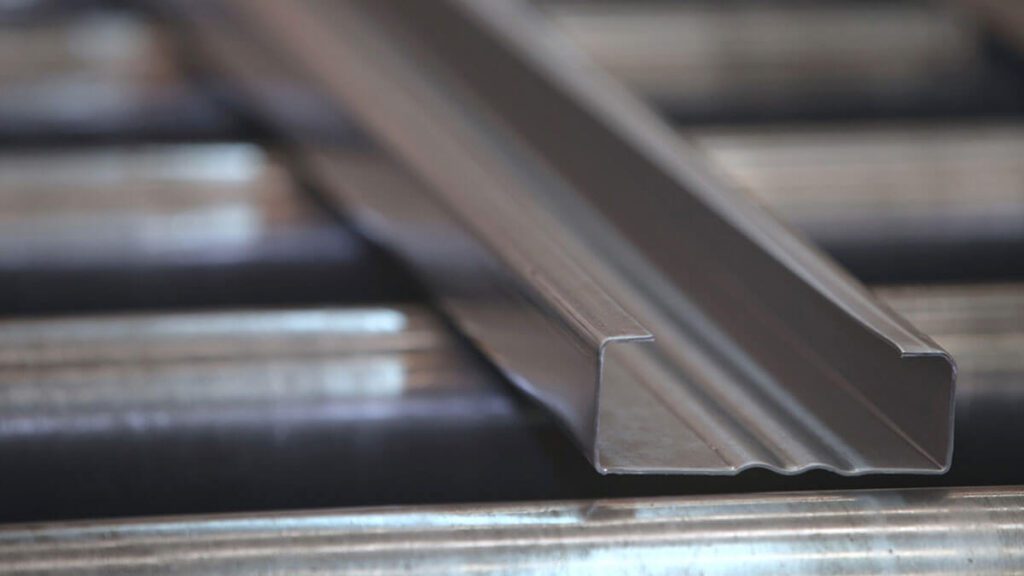

Safety and Durability

Pallet racking systems are designed to handle heavy loads, making them an essential component for ensuring the safety of both employees and products. Quality racking systems are made from durable materials such as steel, providing long-term stability even in the most demanding environments. When installed and maintained properly, they help prevent accidents and damage to products, reducing costly disruptions to warehouse operations.

Supporting Modern Automation

With the rise of warehouse automation and robotic picking systems, pallet racking has adapted to the needs of high-tech logistics. Many warehouses are now equipped with automated storage and retrieval systems (AS/RS) that integrate seamlessly with pallet racks, allowing for even greater efficiency and productivity. This capability positions pallet racking at the heart of the smart warehouse revolution, supporting the growing trend toward automation in logistics.

Conclusion

Pallet racking is far more than just a storage solution—it’s the backbone of modern logistics. Its ability to maximise space, enhance productivity, support safety, and scale with business needs makes it an indispensable asset for any warehouse or distribution center. For businesses looking to stay competitive in today’s dynamic market, investing in the right pallet racking system is a step toward a more efficient and profitable future.

If you’re considering a new pallet racking system or upgrading your current setup, contact Allrack today to discuss how we can tailor a solution to meet your specific needs.